DC GENERATOR

A generator is a machine which converts the mechanical energy

into electrical energy. It works on the principle of Faraday's law of

electromagnetic induction. DC Generators produce the direct current.

Ordinary generator working

The figure

shows two pole and one coil generator, two slip rings are connected with the

two terminals of the coil.

Figure 1: The coil is at 90 degree to the field, there will

be no cutting of flux so no emf is produced

Figure 2: The coil sides are parallel to the field; hence

maximum emf will be induced

Figure 3: The coil is in the same position as in figure 1,

but ab side is downwards and cd is upwards, there is no voltage will be

induced.

Figure 4: It is similar to figure 2, maximum emf is induced

but in the reverse direction.

Figure 5: In this way a cycle of ac voltage is completed.

Commutation

Commutation in a dc machine is the process of converting alternating current into direct current by the help of commutator

Emf equation of dc generator

Φ = flux produced by each poles

P = number of poles in a generator

so total flux produced = Φ x P

Time taken for one revolution = 60/N where N is the speed of armature conductor in rpm

according to Faraday's law, e = dΦ/dt

e = total flux/time taken = Φ x P / (60/N)

that is emf induced in one conductor is

e = ΦPN/60

Z = total number of conductors

A = number of parallel paths

Number of conductors connected in series = Z/A

total induced emf = emf of one conductor x number of conductors connected in series

= ΦPN/60 x Z/A

induced emf of a dc generator e = ΦPN/60 x Z/A

notes A = 2 for wave winding, A = P for lap winding

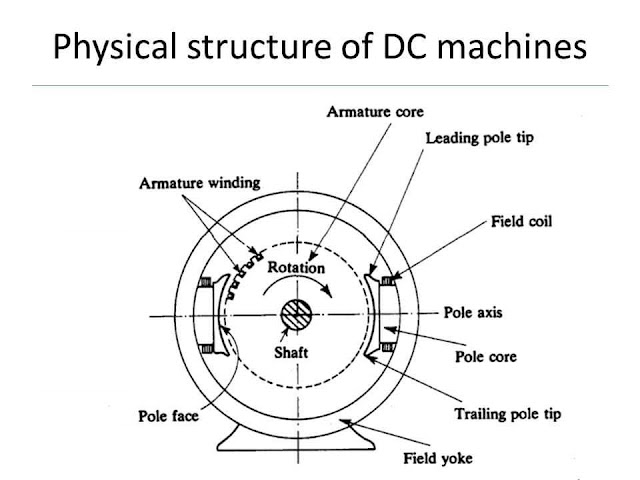

Yoke

The dc generator is fixed in a foundation, this foundation is known as Yoke/body. It is made either cast iron, cast steel or rolled steel. The two main function of yoke are

1) It support the pole cores and provides mechanical protection to the inner parts of machines

2) It provides a low reluctance path for magnetic flux

Armature

The rotating part of the dc machine is called Armature. It consists of

1) laminated core

2) Armature core and Armature winding

Armature core provides a) Easy path for magnetic flux

b) Houses conductors in the slots

Armature winding - The arrangement of conductors and the steel wire around the core. their are two types of Armature winding a) lap winding - for low voltage and high current applications

b) wave winding - for high voltage and low current applications

3) Commutator

It consists of copper bars/segments insulated from each other and from the shaft by a insulator(Mica) pieces. Each commutator segments are connected to the end of armature coils.

Pole Core

The pole core and Pole shoes are either cast with frame or bolted to it. The pole core have the following functions

1) Supports the field/Exciting coils

2) It spread out the magnetic flux

Field Coils

Each pole has one or more field winding's to produce magnetic field. Most commonly the copper wire is used for construction of field coils.

The dc generator is fixed in a foundation, this foundation is known as Yoke/body. It is made either cast iron, cast steel or rolled steel. The two main function of yoke are

1) It support the pole cores and provides mechanical protection to the inner parts of machines

2) It provides a low reluctance path for magnetic flux

Armature

The rotating part of the dc machine is called Armature. It consists of

1) laminated core

2) Armature core and Armature winding

Armature core provides a) Easy path for magnetic flux

b) Houses conductors in the slots

Armature winding - The arrangement of conductors and the steel wire around the core. their are two types of Armature winding a) lap winding - for low voltage and high current applications

b) wave winding - for high voltage and low current applications

3) Commutator

It consists of copper bars/segments insulated from each other and from the shaft by a insulator(Mica) pieces. Each commutator segments are connected to the end of armature coils.

Pole Core

The pole core and Pole shoes are either cast with frame or bolted to it. The pole core have the following functions

1) Supports the field/Exciting coils

2) It spread out the magnetic flux

Field Coils

Each pole has one or more field winding's to produce magnetic field. Most commonly the copper wire is used for construction of field coils.

Brushes

A dc machine consists of two or more stationary carbon brush set held in box type brush holder. They make contact on the commutator with a certain amount of pressure. The pressure exerted by the brushes on the commutator can be adjusted and is maintained at constant value by means of a spring.

Shaft

The shaft is used to transfer mechanical power to the machine. It is made by mild steel with a maximum breaking strength

A dc machine consists of two or more stationary carbon brush set held in box type brush holder. They make contact on the commutator with a certain amount of pressure. The pressure exerted by the brushes on the commutator can be adjusted and is maintained at constant value by means of a spring.

Shaft

The shaft is used to transfer mechanical power to the machine. It is made by mild steel with a maximum breaking strength

ReplyDeleteThe winding machine has kept up unmistakable relationship, for instance, contraption, materials and wire tries. A manual winding machine is having focus on a turn and customers physically doled out the wires, ropes and pulling back materials.coil winding machine

So in like way, the toroidal winding machine has contained with standard stepper motor drive, DC motor drive, and power supplies in a control box. All around, this kind of winding machines has controlled for transformers. automatic toroidal winding machine

ReplyDeleteThe present close think winding machines are as every so often as conceivable used with focuses with square kind of structure yet the new winding model has astonishing execution than existing winding machine. The reason of this winding machine performing mind blowing its procedure on quality level automatic toroidal winding machine

ReplyDelete